Products

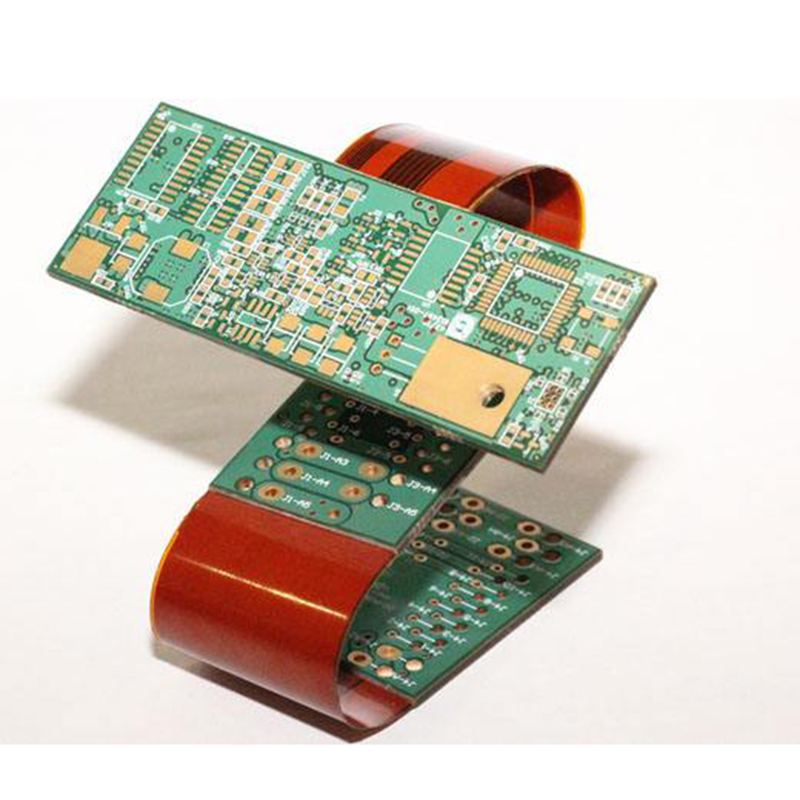

Flex+rigid PCB Assembly Manufacturer

Reasonably plan the circuit pattern to ensure that the soft part can be perfectly combined with the rigid part. Make the rigid part: first make the rigid circuit part, which usually uses conventional rigid boards such as FR-4 materials, and is completed through the traditional PCB production process. Including drawing design, light drawing plate, etching, copper plating and other steps. Making the soft part: use flexible materials such as polyimide film as the substrate material of the flexible circuit, and use photolithography technology to transfer the circuit pattern to the flexible board. Then copper plating and other process steps are carried out to enhance the electrical conductivity of the flexible circuit. Make rigid and flexible connection parts: In the connection area of the rigid board and the flexible board, a special process is used to combine the two, usually by etching grooves or using bonding technology.

Make sure the connections are tight and have a good electrical connection. Component installation: Solder the necessary components on the rigid and flexible circuits, and use SMT or plug-in welding technology to ensure that the solder joints are firm and reliable. Quality inspection and testing: Strict quality inspection and testing of rigid-flex boards, including visual inspection, electrical characteristic testing, and reliability testing. Ensure products meet quality requirements and specifications. Packaging and Delivery: After final inspection, the Rigid-Flex board is properly packaged to protect it from physical damage. Deliver to customers on time. Rigid-flex board production process requires a high degree of technology and experience, and requires strict control and testing to ensure product quality and stability. We will produce according to the above process flow to provide you with high-quality rigid-flex board products.